Seals

Hydraulic Seals: The seals must be capable of resisting extreme temperatures, high pressure and shear force inside the cylinder. These seals must prevent fluid leakage from your cylinder.

Pneumatic Seals: These seals are used to prevent leakage of gases / air. Depending on the application, gaskets are made of, for example, plastic, rubber, cork, graphite or copper, paper, gasket plate, cotton or metals.

Rotating Seals: Shaft seals for your hydraulic pumps, motors, rotary feed-throughs, couplings, crankshafts and wheel hub applications etc. A V-ring is used to stop water and/or dirt.

Hydraulic and/or Pneumatic piston seals, rod seals, cushioning rings, guide rings, and dirt wipers, ... Our profiles can be found in our profile list.

Also the complete overview of our rotary seals, oil seals, high pressure seal rings such as a, axle, ash, c, cs, bs, bss, .... You will find it here.

Our Products

O-rings are the most economical and versatile sealing elements. Thanks to their simple design, they are used in many industrial applications, both static and dynamic. They provide a good seal and are particularly suitable for cases where space is at a premium.

Delivery of many sizes O-rings and O-ring cord from stock.

Various qualities for different applications, both hydraulic and pneumatic.In materials such as rubber, viton, silicone, EPDM, PU

Static seals are used as auxiliary elements to the O-rings. The main objective is to prevent the seal ring from entering the space between the two metal parts.

We have included static seals such as O-rings, D-rings, R-rings, Quad-rings, Square-rings, PFS-rings, FCS-rings in our range. Take a look at our profile list for a complete overview.

Pistonseal Piston seals are located between the piston and the cylinder wall. On the outside, the seal moves linearly and tightly against the stationary cylinder wall. A hydraulic piston seal is the seal mounted in the piston as a fluid seal. A pneumatic piston seal is the seal mounted in the piston against gas leakage.They prevent leakage and ensure that the oil/gas is kept in place. With this oil the pressure is built up on one (single acting) or two sides (double acting) to allow the piston rod to move back and forth.

Guides, guide strips, guide rings, bushings: Guide rings and tape provide the function of resistance to deformation by pressure under radial load and drive the piston and rod in the hydraulic/pneumatic device, reducing friction between the moving parts. without the guide rings, metal contact with the cylinder head would damage the system. Guide rings are used to replace the traditional bronze bushing in hydraulic/pneumatic cylinders in case of insufficient lubrication. We have guide rings as well as guide strips available from stock in different materials for different applications.

Hunger seals and bearing elements are manufactured exclusively from high-quality materials. The elastic elements of the seals are made of wear-resistant polyurethane or special elastomeric compounds (nbr, fpm, epdm, ...). Where economically and technically feasible, PTFE or PTFE compounds are used in seals or to produce complete seals. The use of PTFE can, among other things, increase the service life and efficiency of the equipment. All types of Hunger seals are available... these are only original hunger seals (not aftermarket).

Rod seals are usually placed in the head of a cylinder, where the rod leaves the cylinder. They are used in hydraulic cylinders as a fluid seal and pneumatic cylinders as an air seal.

Hydraulic and/or Pneumatic piston seals, rod seals, damping rings, guide rings, and dirt wipers, ... You will find our profiles in our profile list.

Wipers, dirt wipers, dust rings, scrapers or Wipers, are mounted in a hydraulic/pneumatic cylinder and ensure that the rod is cleaned of dust, moisture or any form of contamination at the return stroke.

They are mainly used in linear dynamic applications. Characteristic are the elastic scraper-lip closure, and the possible metal casing.

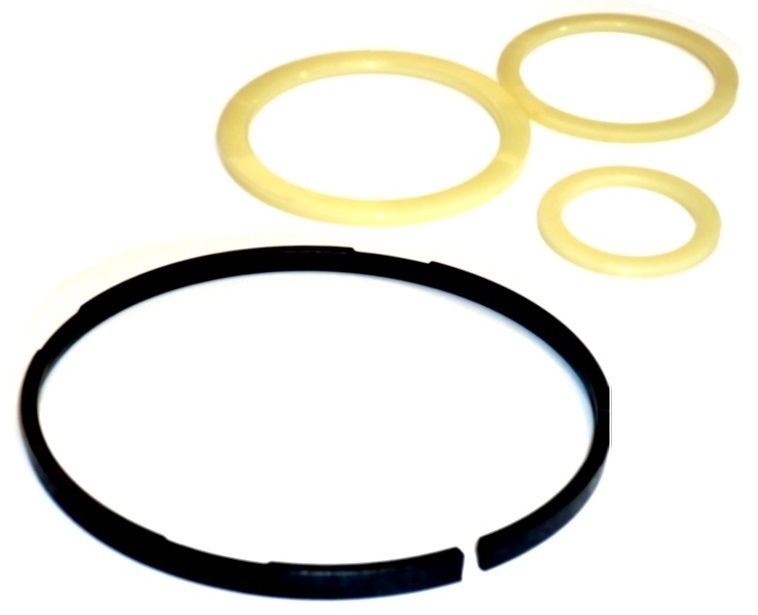

Backup rings or support ring is a rigid thin ring that holds an elastomeric seal or plastic (such as polyethylene) joint in its designed form and in place.

They provide additional resistance support and prevent extrusion of the seal into the housing when under pressure. They do not have a sealing function in themselves but support the actual sealing elements.

These are available in a solid ring, spiral ring or split ring, versions in PTFE with or without filler, NBR or PU, POM, PA, PE, etc....

Cushioning rings are used in many hydraulic cylinders where end braking is required. They consist of 2 rings that are vulcanised. Cushioning rings reduce noise and vibrations.

- Static Seals

Gaskets for moving parts, such as pump shafts, piston rods and valves. Examples include: the stuffing box gasket, the mechanical seal, the shaft seal, the labyrinth seal and the piston ring.

- Dynamic Seals

Gaskets for parts which do not move relative to each other, for example gaskets for flanges, pump covers or the head gasket of an internal combustion engine, are called static seals.

These seals are used as auxiliary elements to the O-rings. The main objective is to prevent the seal ring from entering the space between the two metal parts.

- Double acting seal

A double-acting cylinder can exert pressure as well as tensile force.

Here, a sealing ring is used to seal in two directions, i.e. during the pushing and pulling movement of a cylinder.

- Single acting seal

The cylinder is single acting when it can only apply force in one direction. It is a question of incoming or outgoing stroke. We speak of a pressure cylinder: the force causes the outgoing displacement or of a pulling cylinder if the force causes the ingoing displacement.

In this case, a sealing ring is used to seal in one direction, i.e. when a cylinder is pushed or pulled.

You can also contact us for customization as well as fully assembled sealing kits.

We also offer FDA CURRENT seals especially for the food industry!